This is a basic 100 watt power amplifier designed to be (relatively) easy to build at a reasonable price. It has a better performance (read: musical quality) than the standard STK module amps that are used in almost every mass market stereo receiver manufactured today. When I originally built this thing, it was because I needed a 100 WPC amp and do not want any money. So I designed around parts I had in the store.

The design is actually a standard format, and I’m sure there are commercial entities that are similar. To my knowlwdge, it is not an exact copy of a commercial entity, nor am I aware of any patents on topology. For experienced builders: I am aware that many improvements and adjustments can be made, but the idea was to keep it simple and must do-able by anyone who is a circuit, and has not the patience to do a sloppy job.

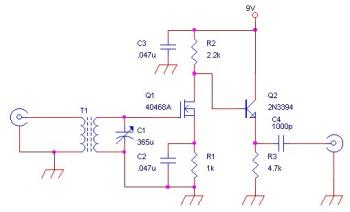

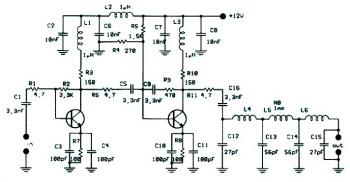

If friend want Bipolar Transistor power amplifier circuit. , In model HIFI OCL 100W RMS. I think this track should be an interesting choice, this circuit is the use of the key transistor BD317 and BD318 unless transistor number BD139, BD140, BC556 too easy then try to buy when the 35V power source with only then build is not difficult for other details as the result of a few See Circuit. Input stage is a BC556 transistor, which most of the open loop gain, and on the serene DC voltage stabilizes. This feeds a level shift stage where the voltage swing to (-) track references. The Transconductance stage is a Darlington, improve frerqency high linearity. The BD317, 318 on a rather large collector-base capacity is dependent on voltage. The BD319 presents this low-z and has a C (ob) of only a few of PF, which is effectively swamped by the pole-splitting 220pF cap. The scene is supplied by BC546 active load (current), which is approximately 20 mA. The current, until the BC556 is limited to about 70 mA in the worst cases.